TM AI Cobot S Series

Category: COMING SOON

COMING SOON

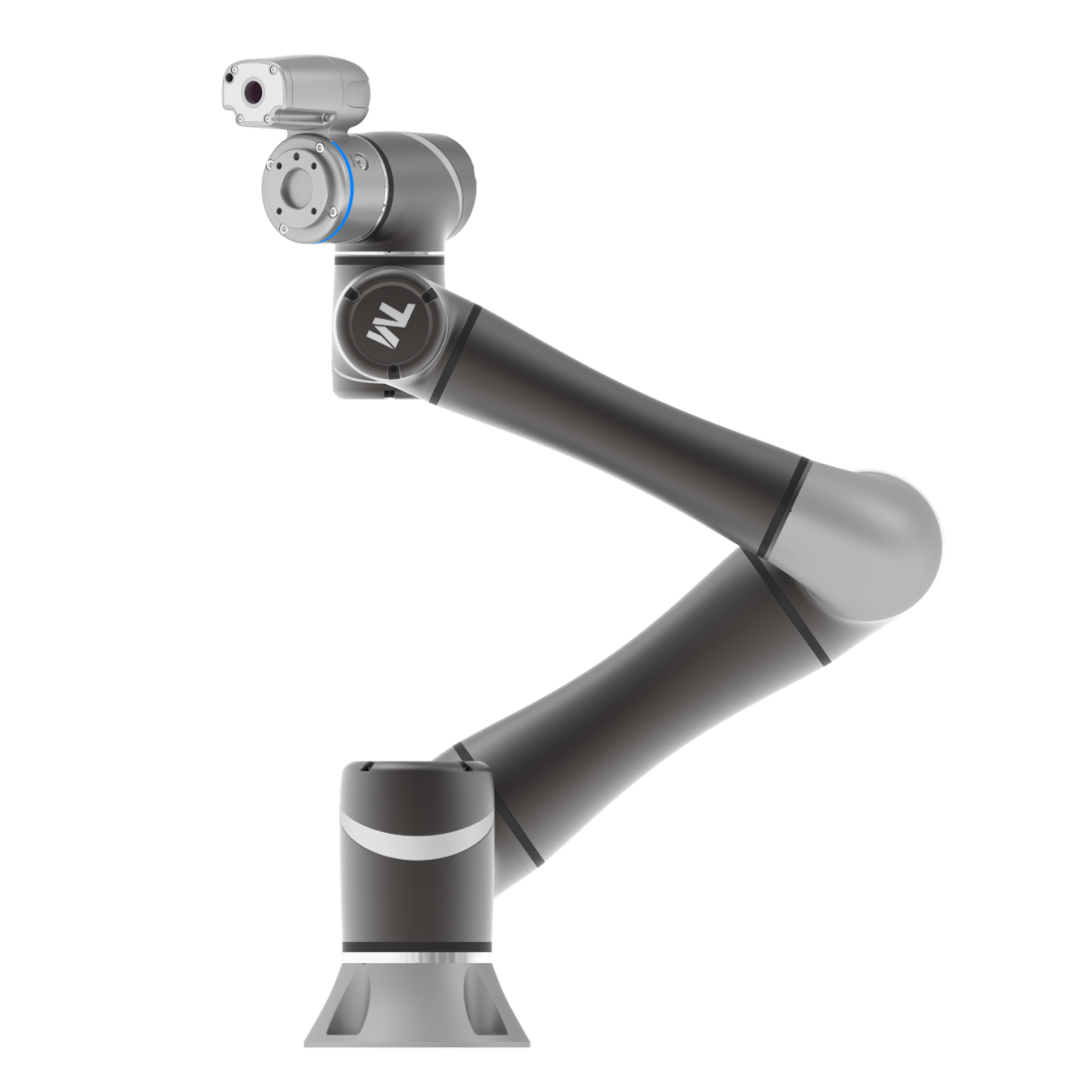

TM6S

Reach

1800 mm

Payload

6 kg

Weight

35 kg

IPIV

54

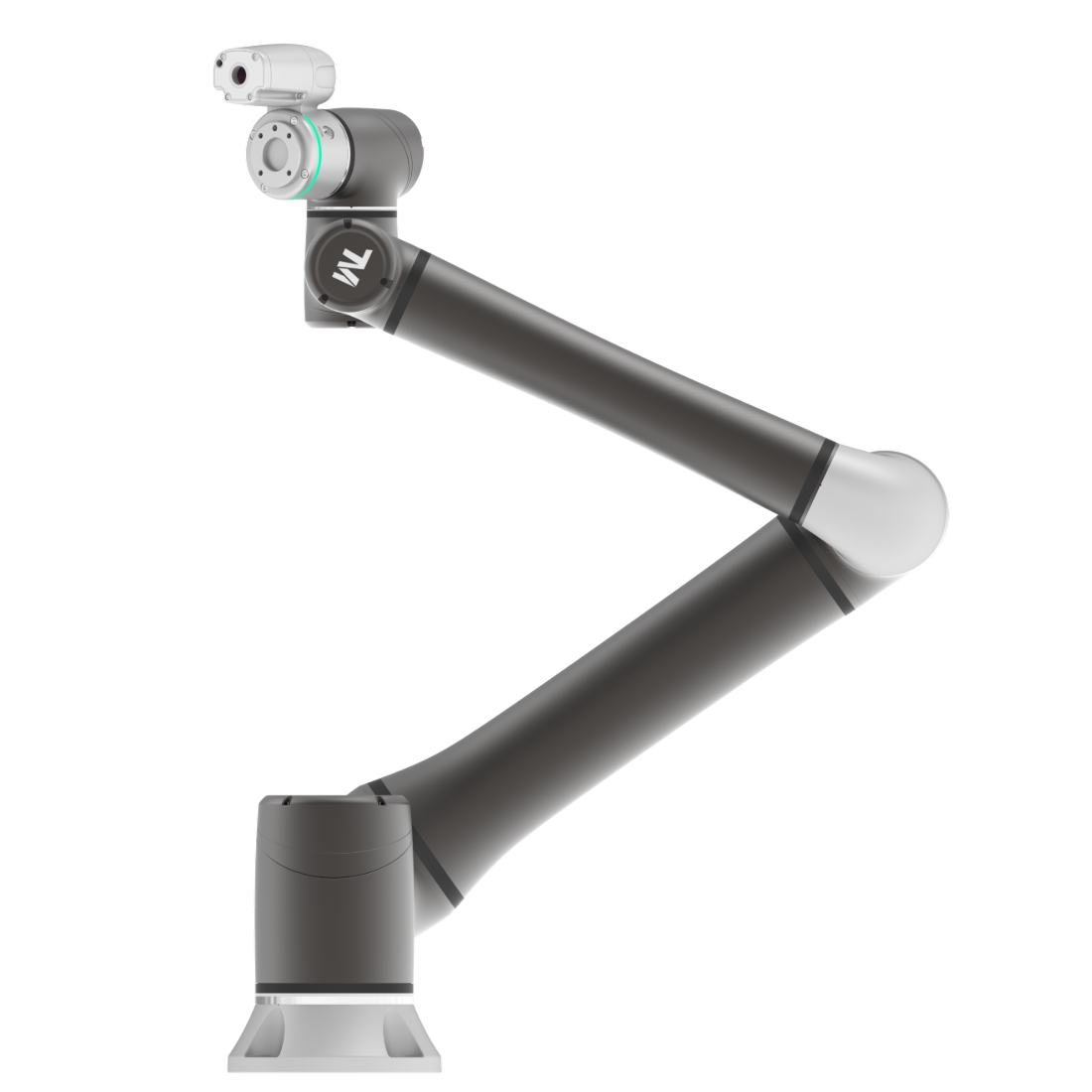

Compact Design, Maximum Efficiency

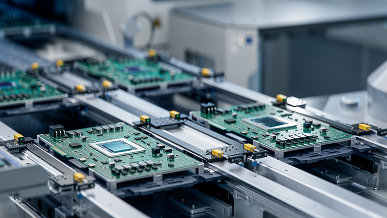

TM5S collaborative robot delivers compact, flexible automation to improve production efficiency and reduce cycle times. Ideal for diverse manufacturing applications, TM5S supports 3D bin picking, assembly, PCB handling, quality inspection, and more — helping businesses boost productivity and streamline operations.

Documentation

* To download the previous version of the 2D/3D file, please visit the file download center.

Specific Feature Support

Semiconductor

The combination of cobot arms and AGV/AMR has received increasing attention from factories and enterprises.

Food Industry

Built with food-grade materials and a hygienic design, ideal for the food and beverage industry’s strict standards for safety, sanitation, reliability, and performance.

Rugged Enviroment

Built for harsh environments, this rugged solution offers superior protection and extended lifespan for reliable, uninterrupted performance.

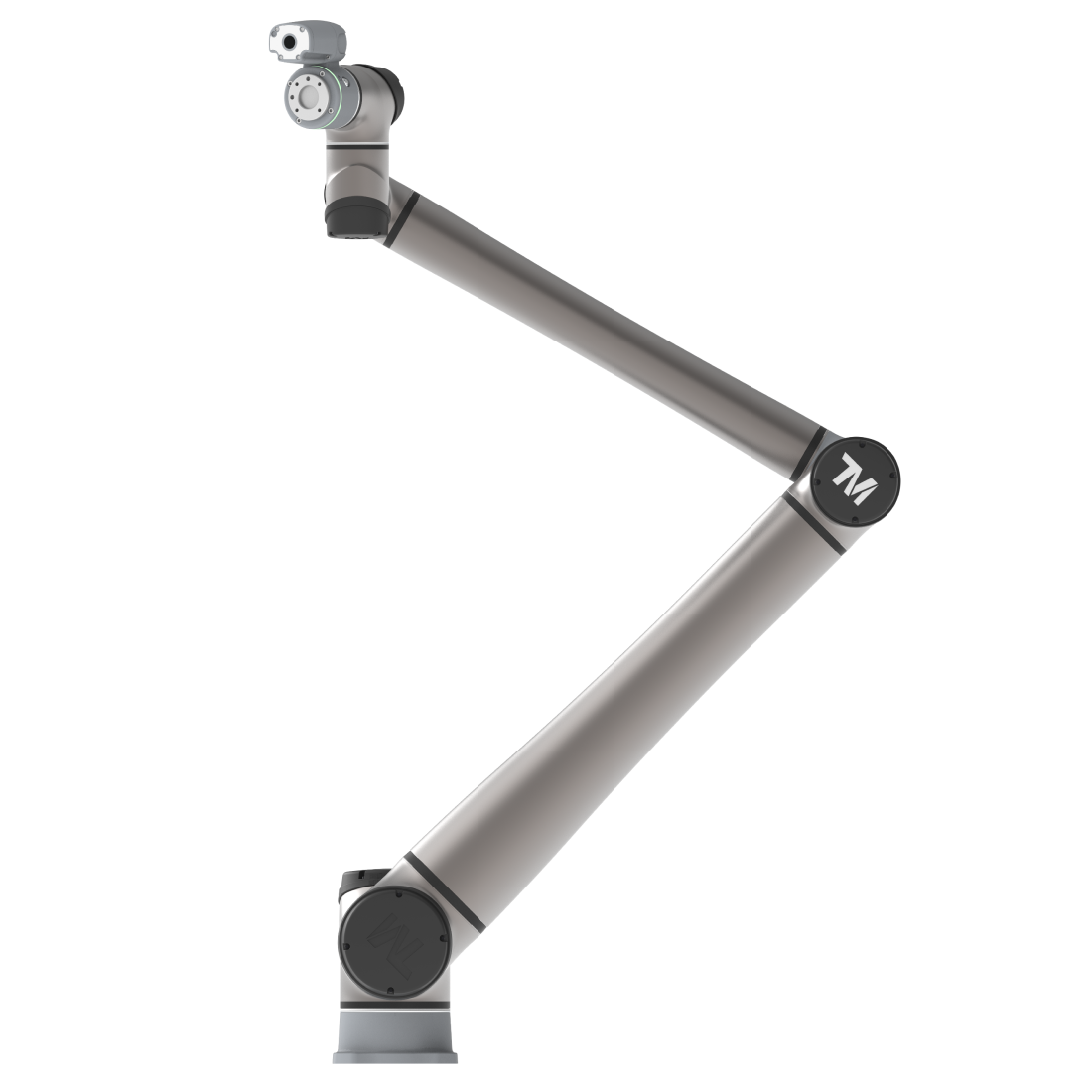

Upgrade to a New Level of Possibilities

Faster

25% faster cycle time!

- The joint speed of the 6th axis is increased from 225 °/s to 450 °/s

- Reduces the cycle time of your production line by 25%* for improved efficiency

More Precise

Best cobot repeatability of ±0.03 mm!

- Delivers up to a 70%* increase in repeatability accuracy of ±0.03 mm

Flexible

Brand New Robot Stick

The enhanced Robot Stick with a 3-position Enabling Switch and a RESET button for easier and safer operation. Use it alone to control the robot with a monitor, keyboard, and mouse.

Attachable TM Screen

Experience versatility in teaching, debugging, and control by combining the Robot Stick with an optional TM Screen. Seamlessly tackle on-site debugging and unlock a wide range of capabilities with this powerful combination.

More Safety Items

Up to 31 Safety Functions Certified by TÜV

Our cobot prioritizes safety above all else, with up to 31 safety functions certified by TÜV. These safety functions comply with the latest version of ISO 10218-1, and are certified as PL d, Cat.3 according to ISO 13849-1, ensuring safety for all possible scenarios.

Worldwide Safety Certification for USA, Canada & Europe

The S series cobot is SGS-certified for UL and CSA in North America and complies with CE requirements for Europe as partly completed machinery. It meets key safety standards, including the Machinery Directive, ISO 10218-1, and ISO 13849-1, and comes with a Declaration of Incorporation.

Its advanced safety functions eliminate the need for additional safety PLCs, reducing costs and effort of safety control configuration and making safety assessments much easier.

Intelligence Amplified, Customization Redefined

AI

Robot Vision Infused with AI Technology

Traditional machine vision requires engineers to manually set up algorithms and rule settings to detect and analyze visual information. This approach can be time-consuming and may not be scalable to handle large amounts of data. In contrast, AI technology utilizes patterns and machine learning to learn decision rules automatically. This allows for more efficient and accurate analysis of visual data, and can ultimately lead to increased productivity and cost savings.

Vision

Unleash the Power of Advanced Vision

The S series cobot is equipped with an integrated vision system featuring advanced AI technology that elevates your manufacturing operations. Pair it with our TM AI+ Training Server solution to unlock the full potential of the cobot’s capabilities and take your vision application to new heights.

Classification

01Object Detection

02Semantic Segmentation

03Anomaly Detection

04TMflow2

More Freedom to Program the Cobot

TMflow is a user-friendly software that allows you to create and edit robot tasks through a graphical interface using a series of function nodes, making it easy for first-time users to learn our flow-based programming without any robotics experience.

If you prefer non-graphical programming, experience a more flexible way to program by using the new Script Node and Script Project. The Script feature allows experienced engineers to program with complex logic and freely edit robot tasks by compiling code. Embrace the method that suits you best and enjoy coding with unparalleled freedom!

TMcraft

Create Personalized Interface with TMcraft for 2nd Development

TMcraft is a new architecture that allows you to create your own customized UI or background program and embed it onto TMflow, our cobot programming software. It offers the freedom to develop third-party plug-and-play applications using C# and WPF development. Additionally, a wizard is available to facilitate the development of high-level applications, such as welding, palletizing, and sanding, making it easier to customize and create the applications you need.

Collaborative Robot Applications

Find the right Cobot for your needs.